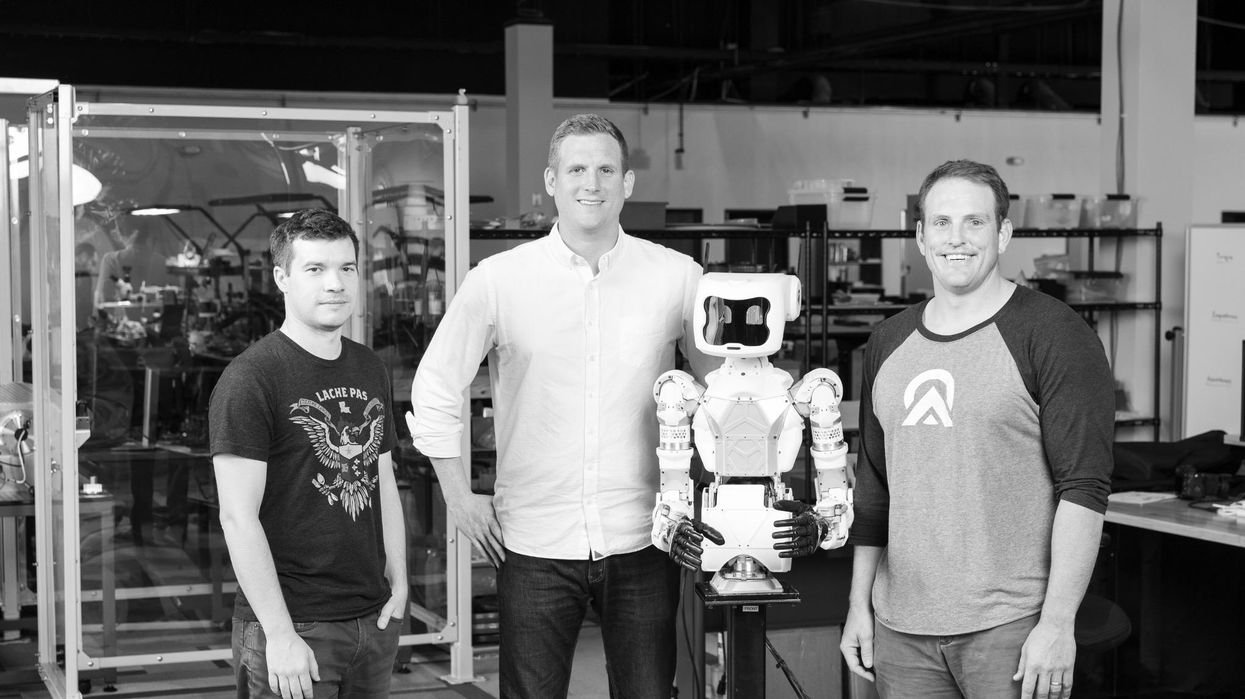

Apptronik, a Texas-based robotics company with its roots in the Human Centered Robotics Lab at University of Texas at Austin, has spent the last few years working towards a practical, general purpose humanoid robot. By designing their robot (called Apollo) completely from the ground up, including electronics and actuators, Apptronik is hoping that they’ll be able to deliver something affordable, reliable, and broadly useful. But at the moment, the most successful robots are not generalized systems—they’re uni-taskers, robots that can do one specific task very well but more or less nothing else. A general purpose robot, especially one in a human form factor, would have enormous potential. But the challenge is enormous, too.

So why does Apptronik believe that they have the answer to general purpose humanoid robots with Apollo? To find out, we spoke with Apptronik’s founders, CEO Jeff Cardenas and CTO Nick Paine.

IEEE Spectrum: Why are you developing a general purpose robot when the most successful robots in the supply chain focus on specific tasks?

Nick Paine: It’s about our level of ambition. A specialized tool is always going to beat a general tool at one task, but if you’re trying to solve ten tasks, or 100 tasks, or 1000 tasks, it’s more logical to put your effort into a single versatile hardware platform with specialized software that solves a myriad of different problems.

How do you know that you’ve reached an inflection point where building a general purpose commercial humanoid is now realistic, when it wasn’t before?

Paine: There are a number of different things. For one, Moore’s Law has slowed down, but computers are evolving in a way that has helped advance the complexity of algorithms that can be deployed on mobile systems. Also, there are new algorithms that have been developed recently that have enabled advancements in legged locomotion, machine vision, and manipulation. And along with algorithmic improvements, there have been sensing improvements. All of this has influenced the ability to design these types of legged systems for unstructured environments.

John Cardenas: I think it’s taken decades for it to be the right time. After many many iterations as a company, we’ve gotten to the point where we’ve said, “Okay, we see all the pieces to where we believe we can build a robust, capable, affordable system that can really go out and do work.” It’s still the beginning, but we’re now at an inflection point where there’s demand from the market, and we can get these out into the world.

The reason that I got into robotics is that I was sick of seeing robots just dancing all the time. I really wanted to make robots that could be useful in the world.

—Nick Paine, CTO Apptronik

Why did you need to develop and test 30 different actuators for Apollo, and how did you know that the 30th actuator was the right one?

Paine: The reason for the variety was that we take a first-principles approach to designing robotic systems. The way you control the system really impacts how you design the system, and that goes all the way down to the actuators. A certain type of actuator is not always the silver bullet: every actuator has its strengths and weaknesses, and we’ve explored that space to understand the limitations of physics to guide us toward the right solutions.

With your focus on making a system that’s affordable, how much are you relying on software to help you minimize hardware costs?

Paine: Some groups have tried masking the deficiencies of cheap, low-quality hardware with software. That’s not at all the approach we’re taking. We are leaning on our experience building these kinds of systems over the years from a first principles approach. Building from the core requirements for this type of system, we’ve found a solution that hits our performance targets while also being far more mass producible compared to anything we’ve seen in this space previously. We’re really excited about the solution that we’ve found.

How much effort are you putting into software at this stage? How will you teach Apollo to do useful things?

Paine: There are some basic applications that we need to solve for Apollo to be fundamentally useful. It needs to be able to walk around, to use its upper body and its arms to interact with the environment. Those are the core capabilities that we’re working on, and once those are at a certain level of maturity, that’s where we can open up the platform for third party application developers to build on top of that.

Cardenas: If you look at Willow Garage with the PR2, they had a similar approach, which was to build a solid hardware platform, create a powerful API, and then let others build applications on it. But then you’re really putting your destiny in the hands of other developers. One of the things that we learned from that is if you want to enable that future, you have to prove that initial utility. So what we’re doing is handling the full stack development on the initial applications, which will be targeting supply chain and logistics.

NASA officials have expressed their interest in Apptronik developing “technology and talent that will sustain us through the Artemis program and looking forward to Mars.”

“In robotics, seeing is believing. You can say whatever you want, but you really have to prove what you can do, and that’s been our focus. We want to show versus tell.”

—John Cardenas, CEO Apptronik

Apptronik plans for the alpha version of Apollo to be ready in March, in time for a sneak peak for a small audience at SXSW. From there, the alpha Apollos will go through pilots as Apptronik collects feedback to develop a beta version that will begin larger deployments. The company expects these programs to lead to full a gamma version and full production runs by the end of 2024.

Source: IEEE Spectrum Robotics