The world’s smallest conventional electronics—devices only nanometers in scale—are typically like any other solid object large or small. When they’re manufactured, they’re molded into a shape, and the item retains that same shape over the course of its functional lifetime. Yet what if nanoscale electronic components and devices could shapeshift? What if they could assume multiple configurations depending on the electric and magnetic signals going into them? Scientists have now provided initial answers to these questions by creating the first nanoscale electronic devices that can physically transform their shape, a feat that may one day lead to more robust microscopic electromechanical gadgets, the researchers find.

Nano-scale electronics are usually static in nature, with their architectures fixed to one form once they are built. “All the materials in these devices are glued together,” says study senior author Javier Sanchez-Yamagishi, a physicist at the University of California at Irvine.

Microelectromechanical systems (MEMS) do possess moving parts. However, require complex, delicate components suspended in space, Sanchez-Yamagishi says.

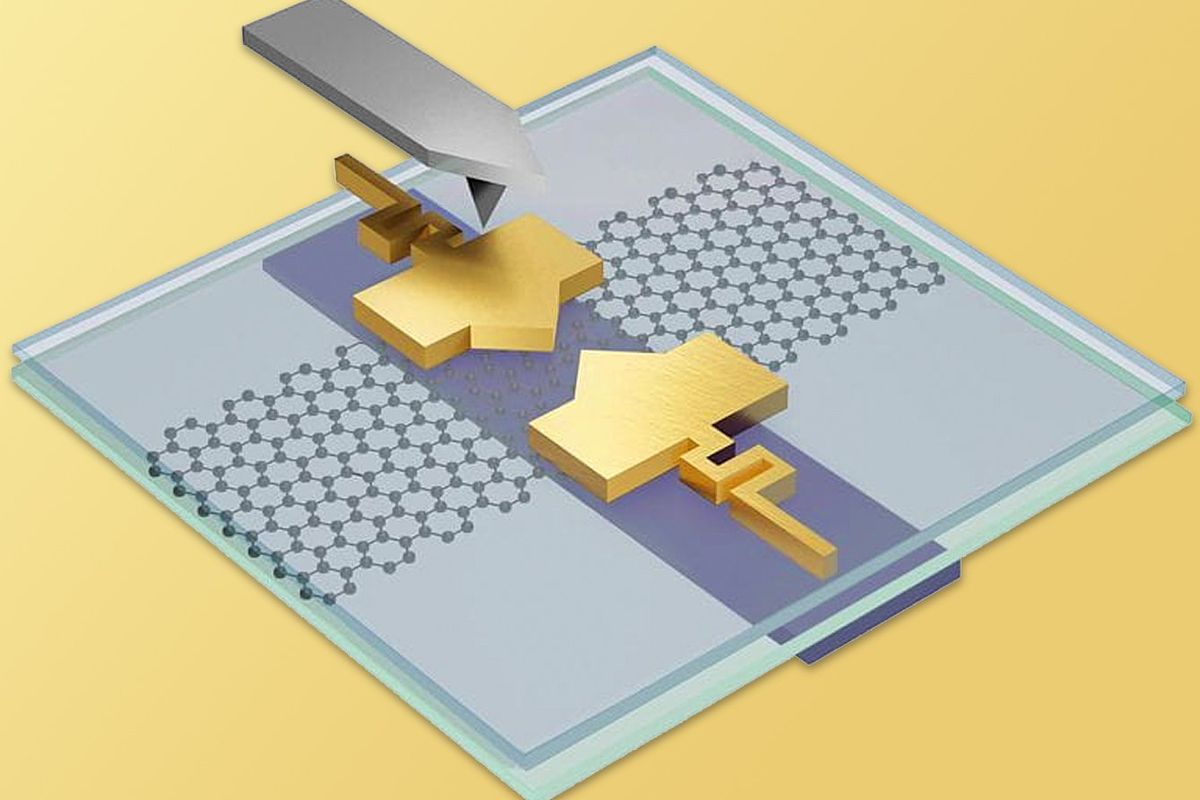

In the new study, the researchers developed the first transformable nano-scale electronic devices. Their parts can slide on surfaces a bit like refrigerator door magnets, letting one modify their structures after they are made.

“What I find most surprising is our ability to move large parts of our micro-scale device repeatedly and quickly over large distances without ripping the whole thing apart, despite the fact that the moving parts are in direct atomic contact,” Sanchez-Yamagishi says.

The scientists did not initially set out to make their discovery. They had thought everything they were investigating would remain static, but when they accidentally bumped into the device, they saw wires move, Sanchez-Yamagishi recalls.

In the new study, the researchers experimented on so-called van der Waals materials such as graphite and hexagonal boron nitride. These materials are made stacked films of smooth atomically thin layers held together by weak electric forces known as van der Waals interactions, the same forces that often make adhesive tapes sticky.

The delicate nature of van der Waals interactions means that anything typically gets only weakly stuck onto the surfaces of van der Waals materials. The scientists found that nano-scale gold wires could slide with very low friction on top of hexagonal boron nitride. This slippery interface let the researchers produce a number of mechanically reconfigurable gadgets, including scanning probe devices potentially useful for microscopy, and extremely sensitive detectors of electric charge potentially useful as readout devices in quantum computers.

“We are able to make mechanically movable devices because the friction between the different materials is low enough to enable sliding without ripping everything apart,” Sanchez-Yamagishi says.

Potential applications for this research are similar to ones for conventional MEMS devices: “electromechanical switches, accelerometers, micro-positioners, optical beam steering,” Sanchez-Yamagishi says. However, “unlike conventional MEMS, our sliding based approach does not require suspended components, enabling in theory a more conventional fabrication process—easier to make—and making the device overall more robust.”

In the future, the scientists hope to make the interfaces more slippery to reduce the power needed to mechanically reconfigure the devices.

“Basically, this boils down to finding a universal dry lubricant that can be integrated into a conventional fabrication process,” Sanchez-Yamagishi says. “Our work offers a proof of concept that shows what is possible and motivates future research in this direction.”

The researchers detailed their findings 7 April in the journal Science Advances.

Source: IEEE Spectrum Telecom Channel