Sensors, controllers, and other electronic devices embedded in clothing could change the way we interact with computers and with each other. But efforts to turn t-shirts into electronic devices have been hampered by the need to power them with bulky batteries and process their data using stiff circuit boards.

Research published today in Science shows that it doesn’t have to be that way. Textiles woven from high-tech layered fibers couple with the body to scavenge electromagnetic energy from the environment—batteries not included. The textiles can also act as simple sensors that are easy to read by eye, or they can beam out a wireless signal. The research team behind the fibers includes Chengyi Hou, Hongzhi Wang, and Qinghong Zhang, who are in the college of materials science and engineering at Donghua University in Shanghai.

The group has demonstrated these smart fibers in a variety of applications. They’ve made a carpet that senses people’s footsteps, a textile-based game controller, a wearable 644-pixel display, and a textile keyboard that can be used to write messages to put on the display.

![]()

The researchers’ wireless textile electronics allow for tactile, patterned-pixel display without chips or batteries.Yang et al.

Engineers have made similarly smart textiles before, including fiber-based touch and pressure sensors. But previous devices all required a connection to rigid power sources and integrated circuits. “You still had to have a board somewhere, in a backpack or in a pocket,” says Yunzhu Li, an electrical and computer engineer at the University of Illinois Urbana-Champaign. Li was not involved with the current research. The new fiber based devices “don’t require anything hard or rigid,” he says. So they have the potential to lower the barriers to more widespread use of smart textiles.

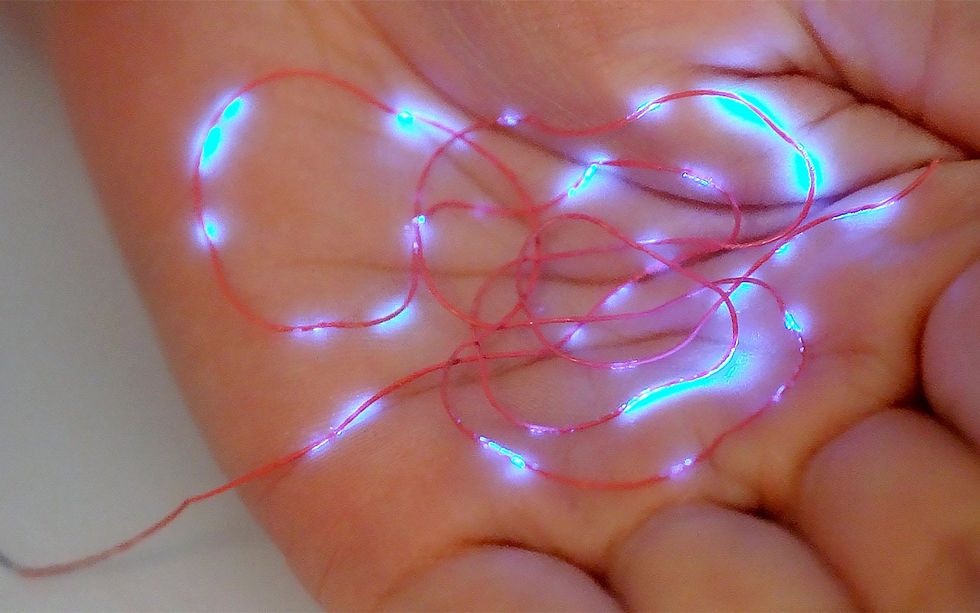

The fibers are made up of three layers. A core of silver-plated nylon fibers acts as an antenna, inducing an electromagnetic field. It’s coated with a dielectric resin layer, which can store the electromagnetic energy that couples to the fiber when a person touches it. Finally, the fiber is topped with an outer layer that lights up in response to that electromagnetic energy. The optical layer is a resin mixed with zinc- and copper-containing phosphor. The fibers can be dyed during manufacturing to change their color.

Simply placing the researchers’ body-coupled fiber on the hand can deliver sufficient power to illuminate it.Weifeng Yang/Donghua University/Yang et al.

The human body is the other critical component. When a person’s fingertip, for instance, gets close to a particular spot on the fiber, charges get stored right at that spot. When enough charge builds up, this excites the optical layer, causing it to light up. And when someone presses a fingertip on the fiber, the charge gets more intense. Above a certain threshhold, this pressure generates a wireless signal. This enables textiles made from these fibers to act as a simple tactile sensor without the need for batteries or logic circuits.

A researcher demonstrates a body-coupled textile that integrates wireless illuminating patterns with a chipless display.Weifeng Yang/Donghua University/Yang et al.

These fibers can be woven into textiles and used to make clothing or carpets. They can also be used as embroidery thread, mixed in with more conventional fibers. Because it’s not necessary to add in any circuit boards or other extras, they can simply be woven using industrial techniques. The researchers tailored the fibers to be comfortable to wear by adjusting their stiffness, smoothness, and other qualities. After 25 washes, the textiles maintain their appearance and performance.

Li says the touch-sensitive fibers could help make it much easier to gather tactile data that’s needed to train robots. Most data in existing models used to teach robots about the world (called “foundational models”) is based on photos and text available on the internet. But we use so much more than visual information to navigate our environment. Feeling how your body contacts a chair helps you know if you’re stable or about to fall over. When cutting up ingredients, it’s not enough to simply watch the movements of the knife. If you can feel whether what you’re cutting is soft like tofu or hard like a carrot, dinner will come out better.

The touch-sensitive electronic fibers are so easy to use, and show such promise for large-scale manufacturing, that it could make it easier to gather huge amounts of real world tactile data to build up more realistic foundation models, says Li. He pictures having people wear these sensors in their clothing or in gloves to gather this kind of information.

“Electronic textiles open up a lot of avenues in ubiquitous computing because textiles are everywhere in daily life,” says Li.

Source: IEEE Spectrum Computing